Alicona µCMM – Optical coordinate measuring machine for complex geometries

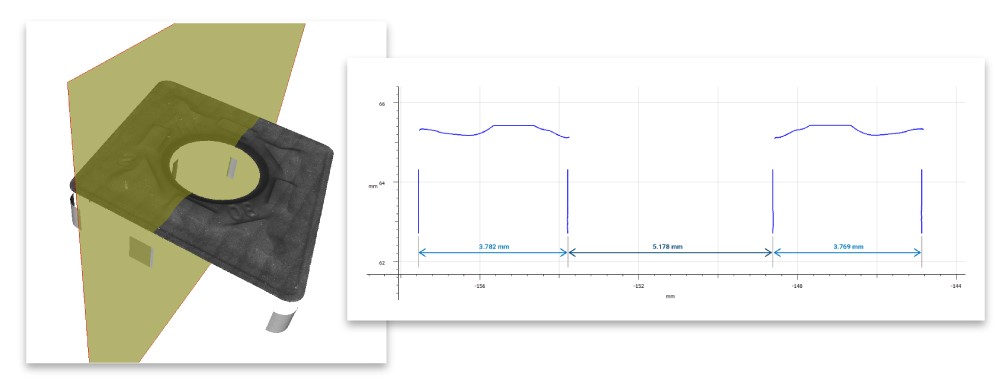

Users combine advantages from tactile coordinate measuring technology and optical surface measuring technology and measure the dimension, position, shape and roughness of components with only one sensor. The optical CMM offers high geometric accuracy of several optical 3D measurements in relation to each other, enabling the measurement of small surface details on large components and precisely determining the position of these individual measurements in relation to each other. The spectrum of measurable surfaces includes all common industrial materials and composites such as plastics, PCD, CFRP, ceramics, chrome, silicon. Simple operation is implemented by single-button solutions, automation and ergonomic control elements such as a specially designed controller. Air-bearing axes with linear drive enable wear-free use and highly accurate, fast measurements.

Technical Specifications

| Measurement principle | non-contact, optical, three-dimensional, based on Focus-Variation |

| Number of measurement points | Single measurement: X: 1720, Y: 1720, X x Y: 2.95 million Multi measurement: up to 500 million |

| Positioning volume (X x Y x Z) | 310 mm x 310 mm x 310 mm = 29 791 000 mm³ |

| Travel speed of axes | Up to 100 mm/s |

| Coaxial illumination | LED coaxial illumination (color), high-power, electronically controllable |

| System monitoring | 9 temperature sensors (accuracy: ± 0.1 K), 3 vibration sensors, internal current and voltage monitoring, incl. long-term logging, retrievable |

| 3D Accuracy 10360-8 The values given are based on ISO 10360-8 and VDI 2617 | EUni:Tr:ODS,MPE = (0.8 + L/600) μm (L in mm)Valid for all MultiMeasurements EUniZ:St:ODS,MPE = (0.15 + L/50) μm (L in mm)Valid for single measurements, height step measurements |

| Objective | 1500A | 800A | 400A | 150A | 80A | |

| Working distance | mm | 23.5 | 17.5 | 19 | 11 | 4.5 |

| Lateral measurement range (X,Y) (X x Y) |

mm mm² |

2.63 6.91 |

1.32 1.71 |

0.66 0.43 |

0.26 0.06 |

0.13 0.01 |