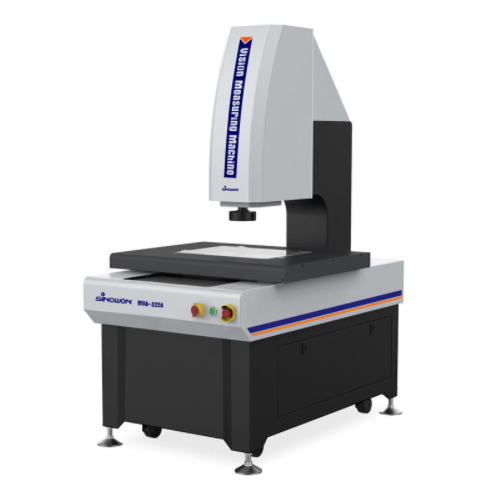

MVS Series Cantilever Automatic Vision Measuring Machine

MVS series is a cantilever high accuracy fully automatic vision measuring machine developed for GD&T measurement with three axis automatic motorized control. It equipped with automatic focusing, automatic lighting control, and automatic movement of hardware and software configuration to make the measurement of linear and geometrical dimensions quickly and accurately.

Product Characteristics

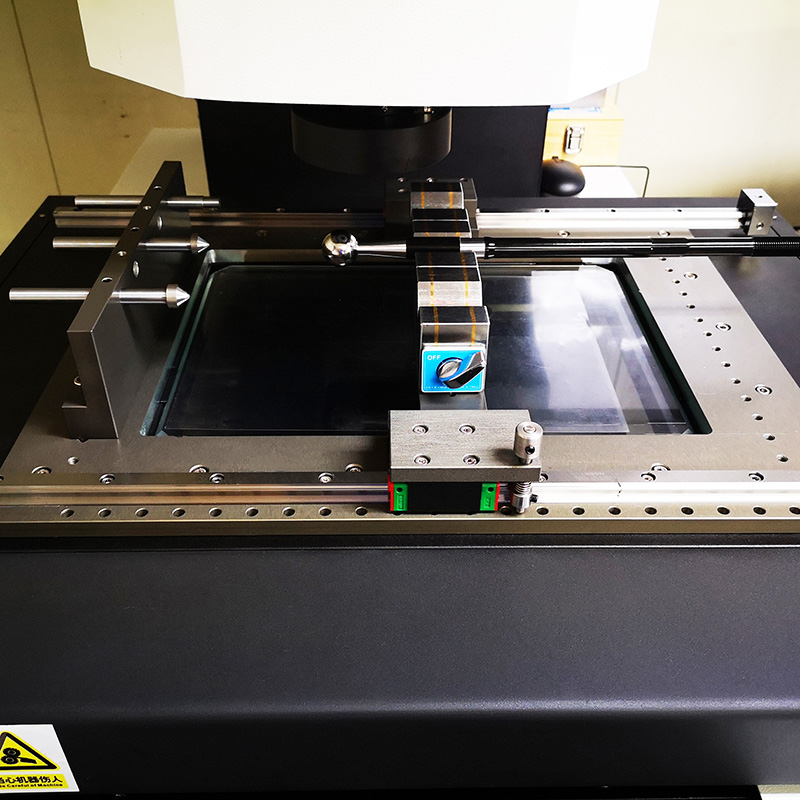

◆ XYZ three axis CNC automatic control and accurate positioning;

◆ Granite base and column, excellent stability;

◆ Precision linear guide, grinding ball screw and AC servo motor etc., to ensure the precision and stability of the motion system;

◆ 0.5 um high precision glass linear scale to ensure the positioning accuracy and measurement accuracy of the system;

◆ High resolution color camera to meet the needs of clear observation and accurate measurement;

◆ 6.5x high-resolution click zoom lens, accurate doubling and one times pixel correction only needed;

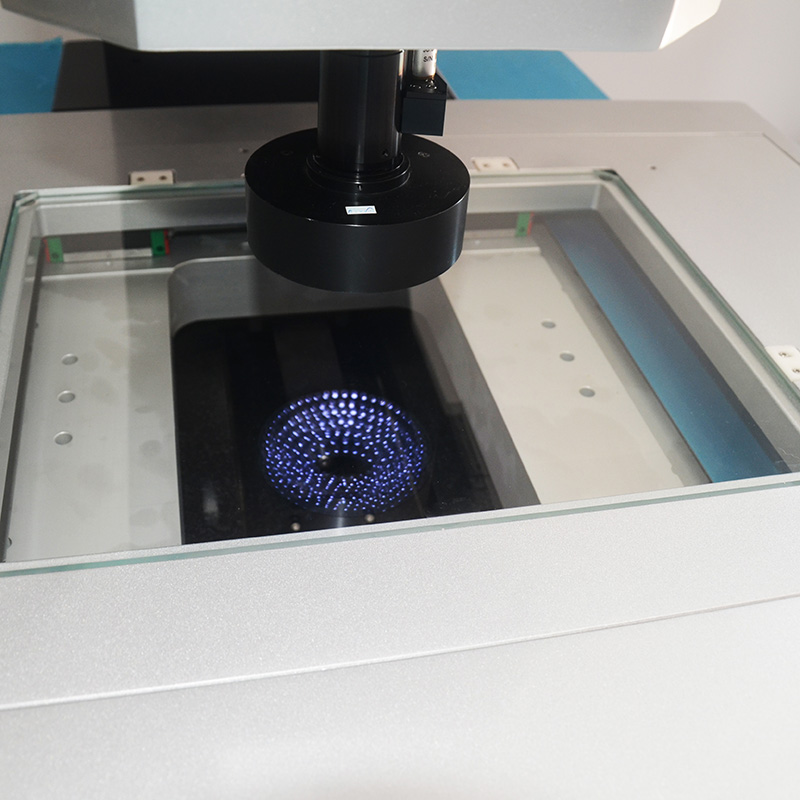

◆ With programmable surface 4-ring 8-division LED Cold Illumination and contour LED parallel illumination and built-in intelligent light adjustment, it can automatic control the brightness in the 8-division;

◆ Powerful function and easy operation iMeasuring 4.1 Measuring Software to enhance quality control;

◆ Automatic measurement program can be set to complete batch measurement efficiently and quickly.

| Product Name | Cantilever Automatic Vision Measuring Machine | ||||||

| Model | MVS-322A | MVS-432A | MVS-542A | ||||

| Code# | 523-360A | 523-370A | 523-380A | ||||

| X/Y-axis Travel | 300x200mm | 400x300mm | 500x400mm | ||||

| Z-axis Travel | 200mm | ||||||

| X/Y/Z-3 axis Linear Scale | Glass Linear Scale Resolution: 0.5um | ||||||

| Guidance Mode | Precision linear guide,double-track double slider guide. | ||||||

| Operation Mode | Joystick controller, Mouse operation, automatic detection program. | ||||||

| Accuracy* | XY-axis:≤2.2+L/200um | ||||||

| Z-axis:≤5+L/200um | |||||||

| Repeatability | ±2um | ||||||

| Video System** | High definition 1/3″ Color CCD Camera | ||||||

| 6.5X continue click zoom lens; Optical Magnification: 0.7X-4.5X;

Video Magnification: 26X~172X(21.5”monitor) |

|||||||

| Field of

View(mm) (D*H*V) |

Magnification | 0.7X | 1X | 2.0X | 3.0X | 4X | 4.5X |

| 1/3″CCD | 8.57×6.86x

5.14 |

6.00×4.80x

3.60 |

3.00×2.40x

1.80 |

2.00×1.60x

1.20 |

1.50×1.20x

0.90 |

1.33×1.07x

0.80 |

|

| Illumination

System |

Contour | LED parallel contour illumination | |||||

| Surface | 0~255 Stepless adjustable 4-ring 8-division LED surface illumination | ||||||

| Measuring Software | Standard: iMeasuring 4.1 Fully Auto Measuring Software | ||||||

| Load Capacity | 25Kg | ||||||

| Working Environment | Temperature 20℃±2℃,Humidity Range<2℃/hr,

Humidity 30~80%, Vibration<0.002g, <15Hz |

||||||

| Power Supply | 220V/50Hz/10A | ||||||

| Dimension(W*D*H) | 1132x720x1665mm | 1280x840x1688mm | 1257x920x1640mm | ||||

| Packing Size | 1290x970x1920mm | 1390x1060x1940mm | 1450x1170x1900 | ||||

| Net Weight | 380Kg | 450Kg | 600Kg | ||||

L is measuring length(mm), the mechanical accuracy of Z-axis and focus accuracy is related to the surface of the workpiece.

**Magnification is approximate value, it is related to the dimension of monitor and resolution.

Field of view(mm) = (diagonal*Horizontal*Vertical)

0.5X or 2X objective is optional available, and realize image magnification: 13X~86X or 52X~344X.

0.1um glass linear scale is optional available.

MVS Series can be customized according to customers’ application requirements. Motorized coaxial zoom lens is optional for improving 2.5D measurement efficiency; MCP probe is optional for measuring 3D geometric dimensions, while laser sensor module is selected to perform the accurate measurement of glass, transparent plastic and other materials.