How to choose Chotest device? You will need to answer a few questions:

- Size of your products (dimensions and weight)

- Quantity of the products (measure at once)

- Required accuracy

- How fast you need to measure?

- Complexity of the task

| Field of View | Φ60 mm – 500×400 mm |

|---|---|

| Accuracy | ±0.7 µm – ±5 µm |

| Repeatability | ±0.1 µm – ±2 µm |

| Load capacity | 2 – 20 kg |

| Z-axis movement | 35 – 200 mm |

| Position of the measured sample | any position |

| color of image | black and white |

| Zoom | digital |

The Chotest VX series encompasses high-precision measuring instruments, commonly used in various industrial applications for accurate measurements.

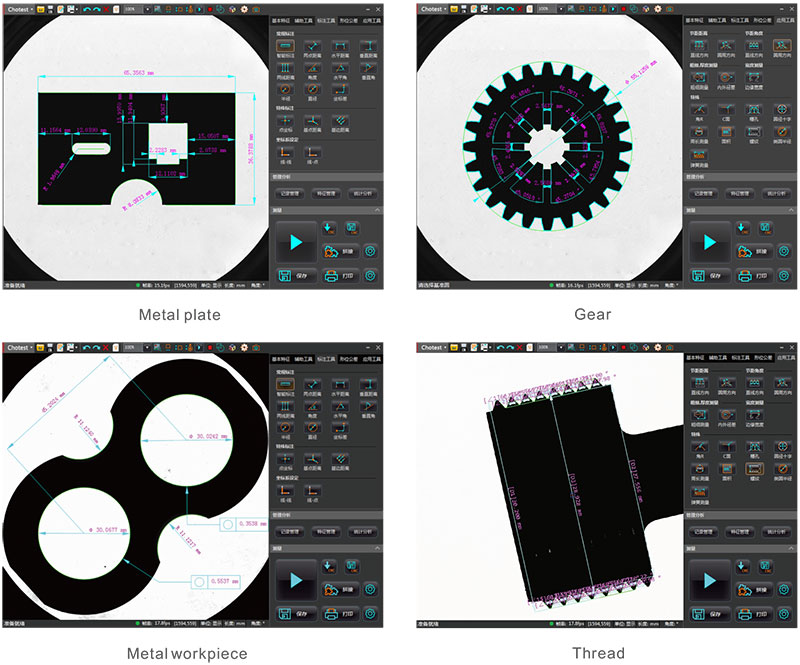

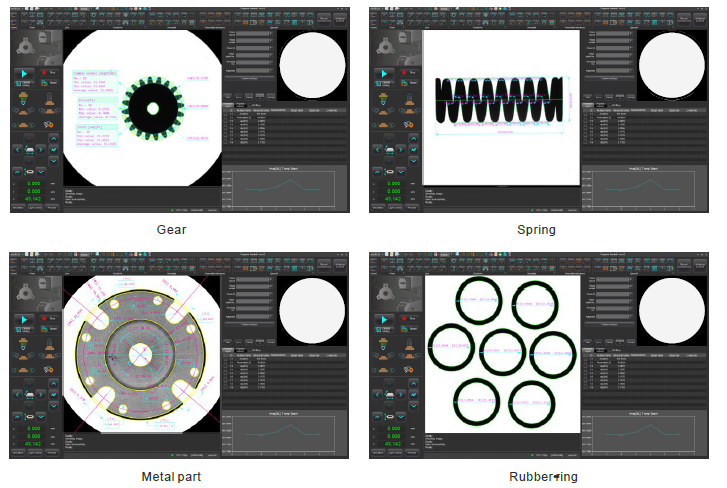

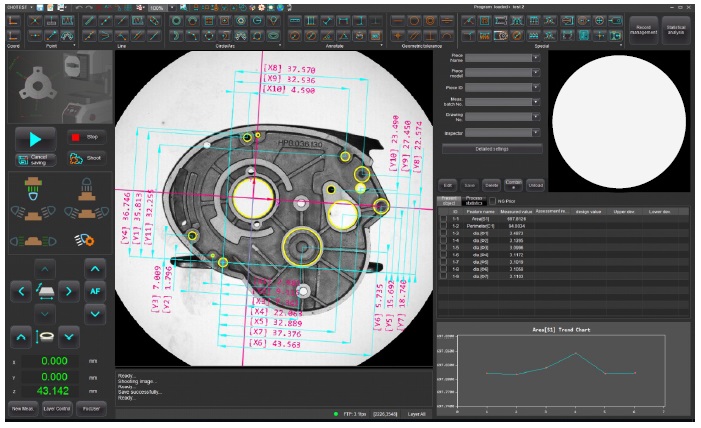

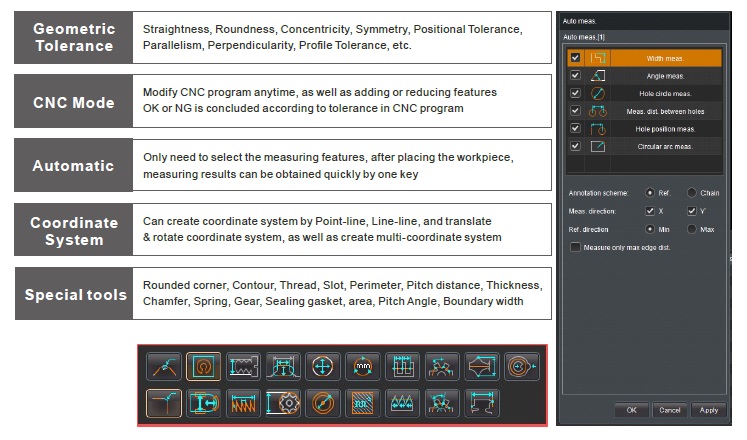

VisionX is a professional measuring software developed by Chotest. VisionX has friendly user interface, convenient operation, powerful and practical functions, support more than 80 kinds of extraction and analysis tools, including feature extraction tool, auxiliary tool, annotation tool and special application tool, etc. Also more function is customizable according to user`s requirements in order to improve the efficiency.

The Chotest VMMs are another line of high-precision measuring instruments, similar to the VX series but with its unique set of advantages and features tailored for specific applications.

Efficient Workflow Integration:

| Travel Range | 300 x200 mm – 1.200 x 1.500 mm Z: 200 mm |

|---|---|

| Accuracy | X/Y : E1x/y ≤±(1.5 +L/200) µm |

| Load capacity | 25 – 50 kg |

| Position of the measured sample | fix position |

| color of image | colorful |

| Zoom | optical |

| Lens | Manual or Motorized |

| Sensor options | Optical probe Touch probe Laser probe |

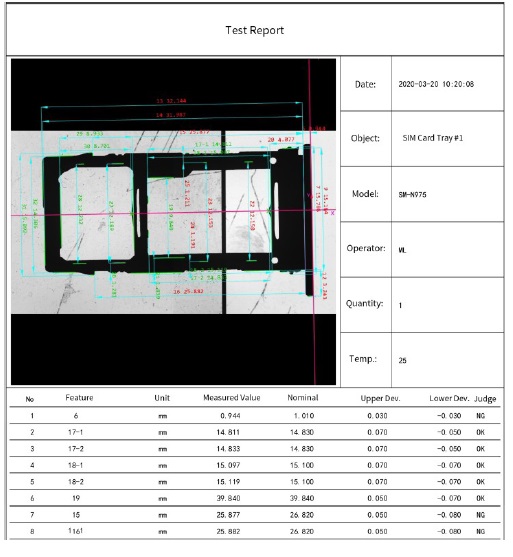

VX Series of Flash measuring machine is widely used in industry of machinery, electronics, mold, injection molding, hardware, rubber, low-voltage electrical appliances, magnetic materials, precision stamping, connectors, connectors, terminals, mobile phones, home appliances, printed circuit boards, medical equipment, watches, tools, etc.

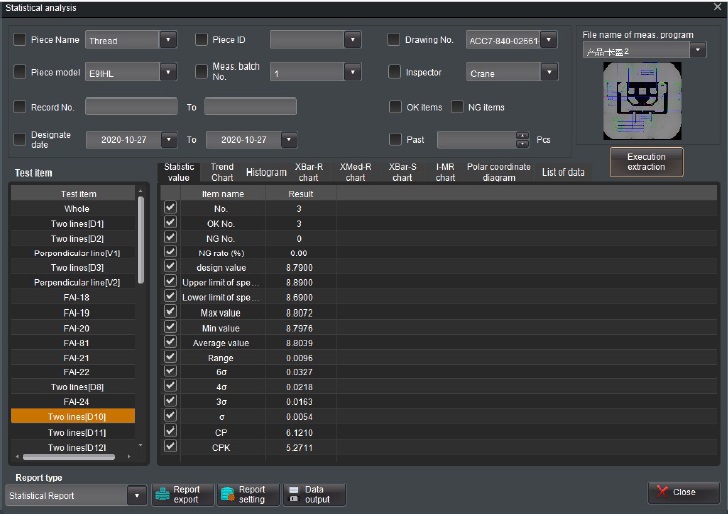

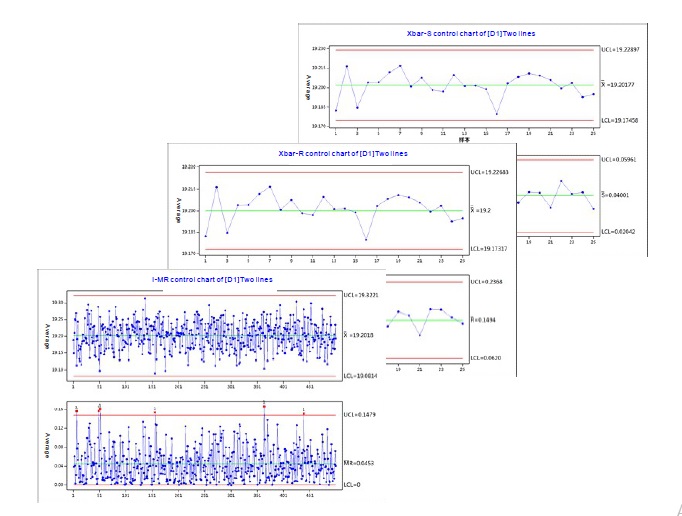

The statistical analysis interface has the tabs of [Statistical Value], [Trend Chart], [Histogram] and [Data List] Automatic recording and query Measurement results and its main statistical information (e.g. average value, σ, 3σ, 6σ, Ca, Cp, Cpk etc) will be automatically recorded and saved. Operator could search records by different conditions.

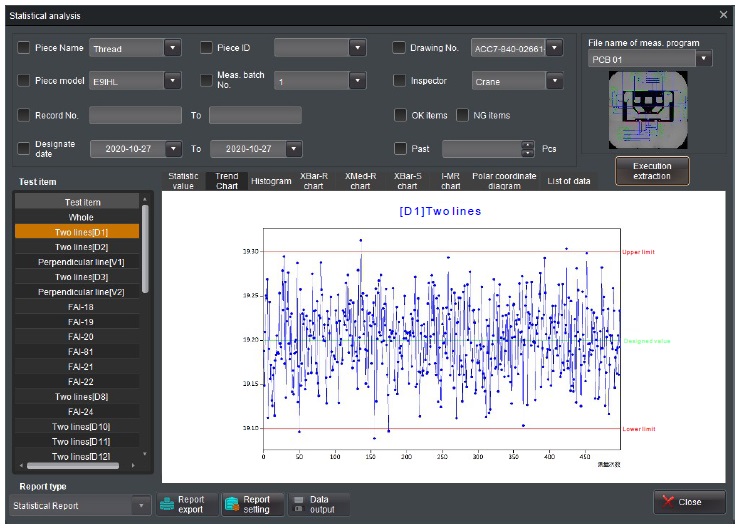

The trend chart monitors the abnormalities of generating equipment and production process by regularly changing trend of measured values. Such as the monotonic and periodic changes of the measured values.

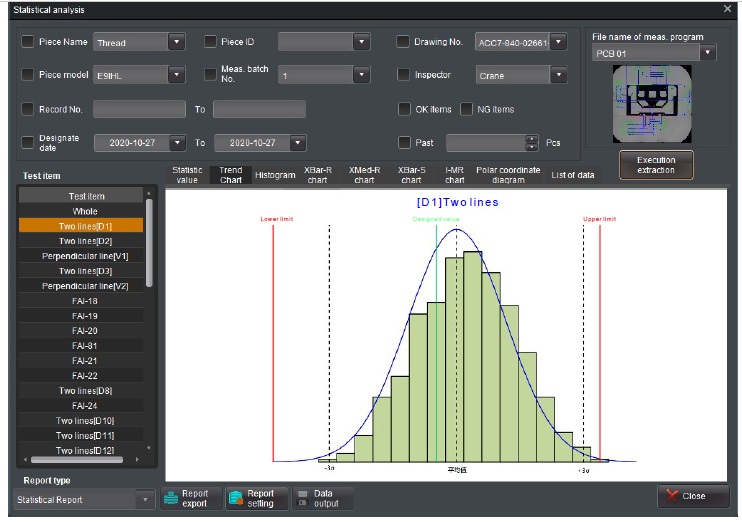

The histogram reflects the fluctuation and distribution of product quality, and transmits information about process quality, which can be used to judge and predict product quality and unqualified rate.

SPC analysis uses statistical methods to monitor product quality and production process trends through quality diagnostic analysis, which is the preventive part in production process and reduce

Our company mainly deals with the distribution of digital microscopes, measuring instruments and their related accessories.

Additionally, we undertake custom measurements (2D, 3D) to find solutions to your problems without investing in a measuring instrument.