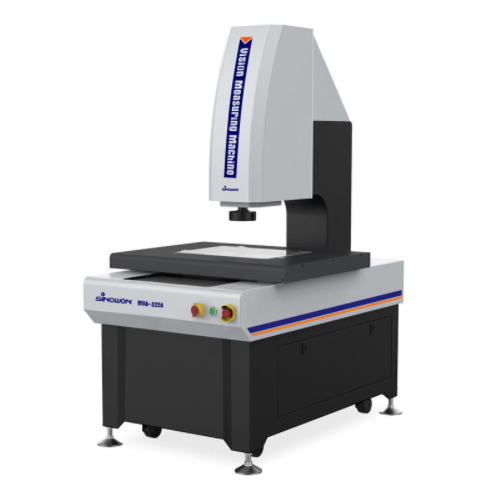

MVA Series Cantilevered Fully Auto Vision Measuring Machine

MVA series is a cantilevered high accuracy fully automatic vision measuring machine developed for GD&T measurement, with three axis automatic control. It equipped with Automatic focusing, automatic lighting control, optimization of hardware and software configuration to achieve the measurement of linear and geometrical dimensions.

Product Characteristics

◆ XYZ three axis CNC automatic control and accurate positioning;

◆ Granite base and column, good stability;

◆ Precision linear guide, grinding ball screw and AC servo motor etc., to ensure the precision and stability of the motion system;

◆ Imported 0.5 um high precision linear scale to ensure the positioning accuracy and measurement accuracy of the system;

◆ High resolution color camera to meet the needs of clear observation and accurate measurement;

◆ 6.5x high-resolution click zoom lens, accurate doubling and one times pixel correction only needed;

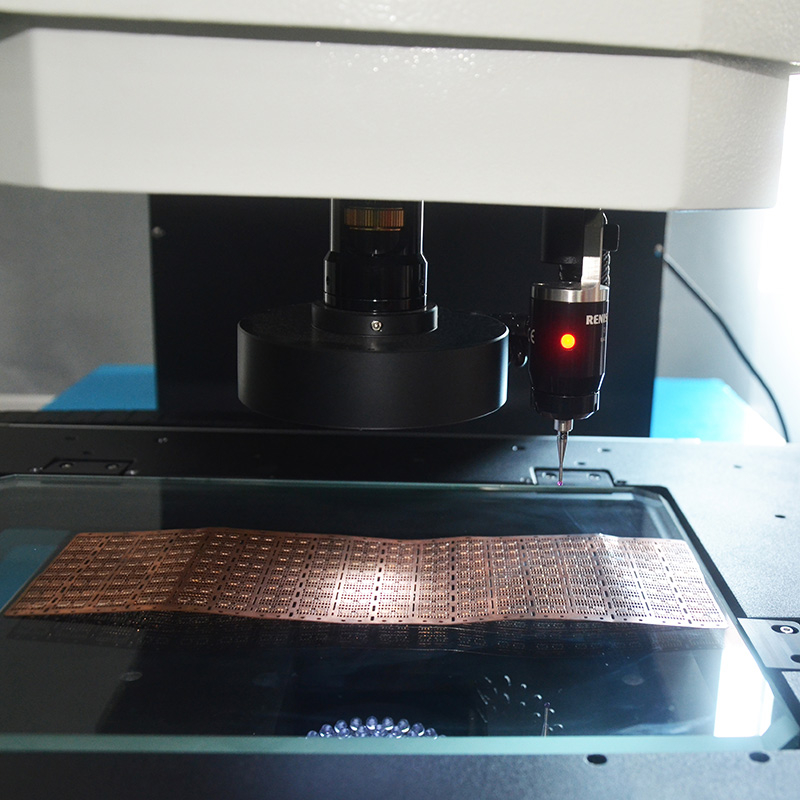

◆ With programmable surface 5-ring 8-division LED Cold Illumination and contour LED parallel illumination and built-in intelligent light adjustment, it can automatic control the brightness in the 8-division;

◆ Powerful function and easy operation iMeasuring 4.1 Measuring Software to enhance quality control;

◆ Automatic measurement program can be set to complete batch measurement efficiently and quickly.

| Product Name | Cantilevered Fully Auto Vision Measuring Machine | ||||||

| Model | MVA-322A | MVA-432A | MVA-542A | ||||

| Code# | 523-360A | 523-370A | 523-380A | ||||

| X/Y-axis Travel | 300x200mm | 400x300mm | 500x400mm | ||||

| Z-axis Travel | 200mm | ||||||

| X/Y/Z-3 axis Linear Scale | Imported Linear Scale Resolution: 0.5um | ||||||

| Guidance Mode | Precision linear guide,double-track double slider guide. | ||||||

| Operation Mode | Joystick controller, Mouse operation, automatic detection program. | ||||||

| Accuracy* | XY-axis:≤2.0+L/200um | ||||||

| Z-axis:≤5+L/200um | |||||||

| Repeatability | ±2um | ||||||

| Video System** | High definition 1/3″ Color CCD Camera, | ||||||

| 6.5X continue click zoom lens; Optical Magnification: 0.7X-4.5X;

Video Magnification: 26X~172X(21.5”monitor) |

|||||||

| Field of

View(mm) (D*H*V) |

Magnification | 0.7X | 1X | 2.0X | 3.0X | 4X | 4.5X |

| 1/3″CCD | 8.57×6.86×5.14 | 6.00×4.80×3.60 | 3.00×2.40×1.80 | 2.00×1.60×1.20 | 1.50×1.20×0.90 | 1.33×1.07×0.80 | |

| Illumination

System |

Contour | LED parallel contour illumination | |||||

| Surface | 0~255 Stepless adjustable 5-ring 8-division LED surface illumination | ||||||

| Measuring Software | Standard: iMeasuring 4.1 Fully Auto Measuring Software | ||||||

| Load Capacity | 25Kg | ||||||

| Working Environment | Temperature 20℃±2℃,Humidity Range<2℃/hr, Humidity 30~80%, Vibration<0.002g, <15Hz | ||||||

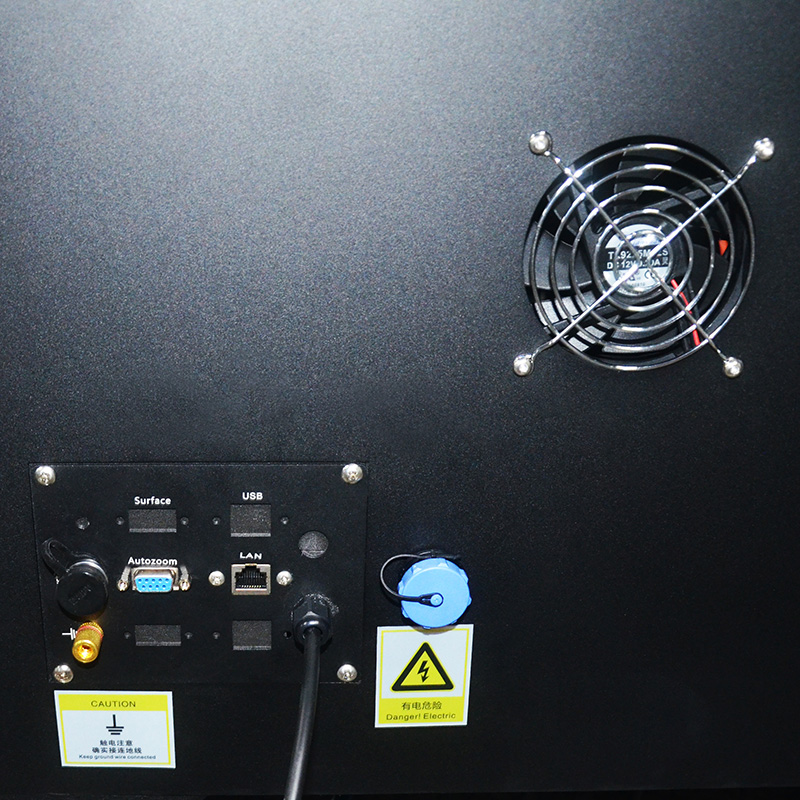

| Power Supply | 220V/50Hz/10A | ||||||

| Dimension(W*D*H) (cm) | 1132x720x1665mm | 1280x840x1688mm | 1257x920x1640mm | ||||

| Packing Size | 1290x970x1920mm | 1390x1060x1940mm | 1450x1170x1900 | ||||

| Net Weight | 380Kg | 450Kg | 600Kg | ||||

L is measuring length(mm), the mechanical accuracy of Z-axis and focus accuracy is greatly related to the surface of the workpiece.

**Magnification is approximate value, it is related to the dimension of monitor and resolution.

Field of view(mm) = (diagonal*Horizontal*Vertical)

0.5X or 2X objective is optional available, and realize image magnification: 13X~86X or 52X~344X.

0.1um imported linear scale is optional available.

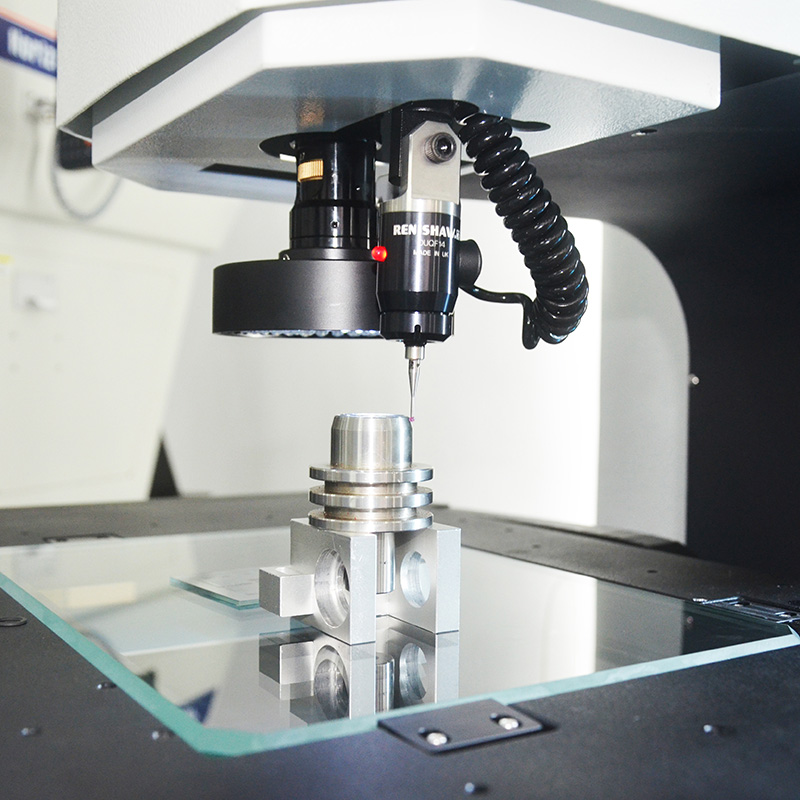

MVA Series can be customized according to customers’ application requirements. Motorized coaxial zoom lens is optional for improving 2.5D measurement efficiency; MCP probe is optional for measuring geometric dimensions, while laser sensor module is selected to perform accurate measurement of glass, transparent plastic and other materials.